INTRODUCTION

Current Problems

Inorganic chemical fertilizers degrade soil

nutrients, causing significant soil acidity.

This is bad for farming. Many countries

struggle with soil acidity, which hinders

plant development. Acidity is the main

yield-limiting factor in 50% of arable

land.

The present distribution chain length

sometimes causes fertilizer shortages,

making farmers’ retail prices exorbitant

since they have to go

through many distribution companies.

The current lengthy manufacturing

procedure limits organic fertilizer growth,

and they may contain diseases, germs, and

heavy metals that

harm plants and people.

What is Active Organic Bio Fertilizer (AOBF)?

An Organic Fast Composting Technology that produces

AOBF for Soil Repair and Soil Recharge to

degraded land to immediately tackle nutrient loss and

improve soil health, protecting soil structure, water

retention, natural nutrient resources, and promoting

microbial eco-system

Combines sustainable innovation with traditional

indigenous farming practices.

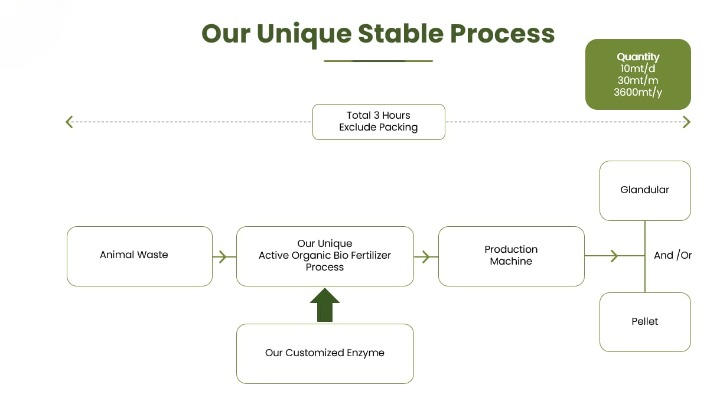

The Technology and Process

Aerobic-Thermophilic microbial fermentation process.

Subjecting feedstock to temperatures of up to 130 degrees Celsius.

Pathogen-free conditions are maintained.

Including customized enzymes into the production process.

Ensuring microbes in the final product by the process.

Rapid production technology of Active organic Bio fertilizer from Animal waste in 3 hours

Multi Organic Waste

Fermenting Machine

Active Organic Bio Fertilizer

1. Quick-transfer Fertilizer technology is a technology that is used to convert

multi-organic waste such as organic waste livestock manure such as chicken,

goat, and kitchen waste and other types of organic waste into probiotic organic

fertilizer in a short time (3 hours).

2. Organic Waste is converted into high quality probiotic active bio organic

fertilizer with the help of our unique customize enzyme.

3. This method enables the manufacturing of organic bio fertilizers that are proved

to be of excellent quality, while maintaining acceptable production costs.

Production Process Comparison

Aspect | Traditional Method | Quick Transfer Fertilizer Technology (QTFT) |

Production Time | 3 -7 days | 2 - 3 hours |

Production Area | Imperative Large space | 200 M2 |

Environmentally friendly | Not environmentally friendly, smells and produces hazardous waste | Environmentally friendly, odorless and waste free |

Quality | Nutrient fertilizer products are not stable | A nutritionally stable fertilizer product full of beneficial good bacteria |

Availability | Fertilizer can not be used immediately (depending on conditions) | Fertilizer can be used immediately, with good quality standard |

7 Key Benefits

Regenerative Agriculture

Our AOBF has consistent high active microbes boosting soil nutrients,

stabilizing soil health, structure and water retention; as a result, farmers

enjoy healthy soil, growing healthy crop with higher yield and strength

against abiotic stresses.

Fast

AOBF machine converts multi-organic waste

into probiotic organic fertilizer in just 3 hours,

thanks to our unique enzyme efficiency

Superior Catalyst Bio enzyme

Our thermophilic bio enzyme at high temperature speeds up decomposition

of raw organic material, delivering the highest quality of plant available

nutrient in our AOBF product while removing all toxic pathogens

Efficient

Our AOBF machine is fully automated and can

be safely handled by just 1 supervisor and 2

handy workers for 12-hour operations per day,

ensuring operational excellence.

Ops Excellence

Our highly efficient AOBF machine delivers

with zero wastage reducing production costs.

Circular

The process is circular zero waste, creating a

safe and pleasant working environment and

conforms to a clean neighborhood.

Small

With an outstanding small footprint of just

200sqm, our AOBF machine fits anywhere

on-site or nearby waste source locations to

reduce or eliminate logistics.